Magalasi otayira ndi mtundu wa zinyalala zapakhomo, kukhalapo kwake sikuti kumangobweretsa mavuto ndi kusokoneza kupanga ndi moyo wa anthu, komanso kumabweretsa kuipitsa chilengedwe, kumakhala m'malo amtengo wapatali, ndikuwonjezera katundu wa chilengedwe. Akuti China imapanga matani pafupifupi 3.2 miliyoni a magalasi otayira chaka chilichonse, zomwe zimapangitsa pafupifupi 2% ya zinyalala zonse za m'matauni. Chifukwa cha kukulitsa mphamvu ya dziko lonse komanso kusintha kwa miyoyo ya anthu, kuchuluka kwa magalasi otayira kwawonjezekanso. Ponena za kubwezeretsanso ndi kugwiritsa ntchito magalasi otayira, mayiko ena otukuka ku United Kingdom ndi United States apeza zotsatira zodabwitsa. Mayiko aku Europe ndi America agwiritsa ntchito bwino magalasi otayira m'mapulojekiti omanga, yomwe ndi njira yothandiza yogwiritsira ntchito magalasi otayira ambiri. Chifukwa mitundu yonse ya magalasi otayira sikufunika kusankhidwa, palibe chifukwa chofuna mtundu. Mwachitsanzo, magalasi otayira amakonzedwa ngati zinthu zokongoletsera nyumba mu Mosaic. Monga wopanga magalasi otayira, mphero ya magalasi otayira yopangidwa ndi HCM Machinery imapereka chithandizo chabwino cha zida zobwezeretsanso magalasi otayira. Lero, tiyambitsa njira yopangira magalasi otayira magalasi otayira.

1. Kupindulitsa miyala ya phosphate: Kupindulitsa miyala ya phosphate ndi gawo loyamba pakupanga miyala ya phosphate, yomwe cholinga chake ndi kulekanitsa mchere wothandiza ndi zosafunika zomwe zili mu miyala ya phosphate pogwiritsa ntchito njira zakuthupi ndi zamankhwala. Njira zodziwika bwino zopindulitsa zimaphatikizapo kulekanitsa mphamvu yokoka, kuyandama ndi kulekanitsa maginito. Kulekanitsa mphamvu yokoka kumagwiritsa ntchito kusiyana kwa kuchuluka kwa mchere mu miyala kuti kulekanitsa, kuyandama kumagwiritsa ntchito kusiyana kwa kuyandama kwa mchere mu miyala kuti kulekanitsa, ndipo kulekanitsa maginito kumagwiritsa ntchito kusiyana kwa maginito kwa mchere mu miyala kuti kulekanitsa.

2. Kuphwanya ndi kupukuta miyala ya phosphate: miyala ya phosphate ikatha kukonzedwa, imafunika kuphwanyidwa ndi kukonzedwa, kuti itulutse bwino mchere wothandiza mu miyala. Kuphwanya nthawi zambiri kumagwiritsidwa ntchito ngati chotsukira cha jaw, chotsukira cha cone ndi zida zina kuti iswe miyala ya phosphate kukhala tinthu toyenera. Kuphwanya ndi kugwiritsa ntchito makina akuluakulu opangira ndi kukonza ufa wa phosphate kuti iphwanyidwe bwino miyala yophwanyidwa, kuti ikwaniritse zofunikira za fineness.

3. Kuchotsa phosphate rock: Kuchotsa phosphate rock ndi gawo lofunika kwambiri pakupanga phosphate rock, momwe zosakaniza zothandiza monga phosphate zimatha kusungunuka kuchokera mu ore. Njira zomwe zimagwiritsidwa ntchito kwambiri pochotsa phosphate ndi monga kuchotsa acid rock, kuchotsa alkali rock ndi kuchotsa oxidation rock. Kuchotsa acid rock kumagwiritsa ntchito acid solution kuti isungunuke phosphate, kuchotsa alkaline rock kumagwiritsa ntchito alkaline solution kuti isungunuke phosphate, ndipo kuchotsa oxidative rock kumagwiritsa ntchito oxidizing agent kuti isungunuke phosphate.

4. Kuvunda ndi kusefa kwa phosphate ores: Pambuyo pochotsa madzi, yankho la zinthu zothandiza monga phosphate liyenera kutsukidwa ndikusefedwa kuti lilekanitse zinthu zolimba za phosphate. Kuvunda ndi kugwiritsa ntchito chothandizira kudzunda kuti asinthe gawo la phosphate la yankho kukhala chovunda cholimba, ndipo kusefa ndi kulekanitsa dothi ndi yankho pogwiritsa ntchito zida zosefera.

5. Kuumitsa ndi kupukuta miyala ya phosphate: Pambuyo poti matope asefedwe, amafunika kuumitsa ndi kupukuta kuti apeze phosphate yomalizidwa. Kuumitsa ndi kugwiritsa ntchito zida zowumitsira kuti madzi omwe ali mu matope aswe, ndipo kupukuta ndi kuumitsa matopewo pa kutentha kwambiri, kuti apange tinthu tambiri ta phosphate.

6. Kukonza ming'alu ya phosphate: Njira yokonza ming'alu ya phosphate imapanga ming'alu ina, ming'aluyi ili ndi mchere ndi zinyalala zosachotsedwa. Pofuna kuchepetsa kuipitsidwa kwa chilengedwe ndi kuwononga chuma, ming'aluyi iyenera kukonzedwa. Njira zodziwika bwino zochizira ming'aluyi zikuphatikizapo kuyika ming'alu ya ming'alu, kubwezeretsanso ming'alu ya ming'alu ndi kugwiritsa ntchito ming'alu yonse.

Njira yopangira magalasi obwezeretsanso zinyalala: njira yosungunula ndi njira yosungunula nthawi zambiri imagwiritsidwa ntchito, ndipo njira yopangira njira yosungunula ndi ceramic Mosaic ndizofanana. Njira yayikulu yopangira ndikupukuta galasi lotayira kudzera mu mphero yagalasi kuti ikwaniritse zofunikira za ufa wagalasi, kenako ndikuwonjezera kuchuluka kwa chinthu chomata (chosapanga kapena chachilengedwe) ndi chopaka utoto kapena chochotsa utoto, ndi chosakanizira kuti chisakanizidwe kukhala chophatikizika chofanana. Chosakanizacho chimakanikizidwa m'mawonekedwe osiyanasiyana pogwiritsa ntchito njira youma yokanikiza, ndipo thupi louma limatumizidwa ku ng'anjo yozungulira, uvuni wa mbale yopondereza ndi uvuni wa tunnel ndi kutentha kwa madigiri 800-900 Celsius kuti chisungunuke. Nthawi zambiri, chimakhala pamalo otentha a sintering kwa maola 1.5-2.5. Zinthu zoziziritsira mu uvuni kuti ziwunikidwe, kuyikidwa, kuumitsa, kuyang'aniridwa, kulongedza, kusungira kapena fakitale, zinthu zosayenerera zimabwezeretsedwanso. Njira yosungunula imachokera ku magalasi otayira (kuchuluka kwa anthu ndi 25-60%) ngati zinthu zazikulu zopangira, kuwonjezera kuchuluka kwa mchenga wa silika, feldspar, limestone, soda ash ndi emulsion agent, chopaka utoto kudzera mu makina opera magalasi otayira kukhala ufa wofanana, kenako nkulowa mu uvuni wosungunuka wotentha kwambiri (kutentha kosungunuka ndi 1400-1500) kuti usungunuke kukhala madzi ofanana agalasi. Madzi agalasi amalowa mu kalendala ndipo amakanikizidwa mu galasi la kukula ndi mawonekedwe enaake, lomwe limatumizidwa ku uvuni wotenthetsera. Zinthu zotenthetsera zimatha kusungidwa kapena kutumizidwa pambuyo poyang'aniridwa, kuyikidwa ndi kupakidwa.

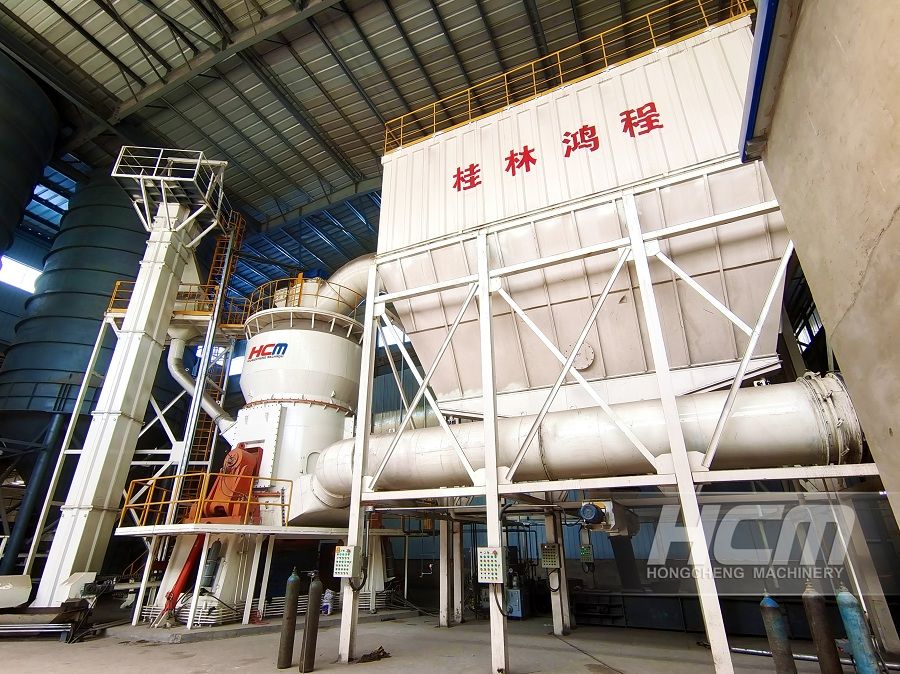

Kubwezeretsanso zinyalala zamagalasi Zojambula zagalasi zimachokera ku kupukuta zinyalala zamagalasi kukhala ufa wagalasi. Mphero yagalasi ndi chipangizo chopangira ufa wagalasi. Mphero yagalasi yotayira yopangidwa ndiMakina a HCM has HC, HCQ and other models, which can process 80-400 mesh glass powder with large output, low energy consumption, small equipment area and simple technology. If you have waste glass recycling needs, welcome to call us to learn more about waste glass mill equipment:hcmkt@hcmilling.com

Nthawi yotumizira: Januwale-08-2024